HISTORICAL PERSPECTIVE

The year was 1939 and a young engineer named Homer T. Seale opened a company in a small Los Angeles, California building utilizing two automatic screw machines to manufacture and sell small parts to the aircraft industry. With the outbreak of World War II, the aircraft parts business flourished and the company rapidly expanded to operate on three shifts employing approximately 80 workers to satisfy the demand for military aircraft. However, along with the celebration of peace that would occur in 1945, came an abrupt end to the aircraft industry job shop work. Mr. Seale then began to search for new products of his own to manufacture and sell.

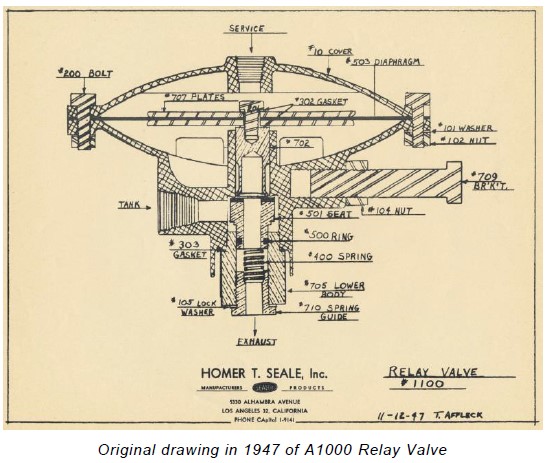

A number of different products were made and sold under the brand name Sealco over the next few years including shower heads, lawn sprinklers, hydraulic jacks and ball point pens. In 1947 production began on a patented relay emergency air brake valve with six full time employees. That valve was the forerunner of the present-day A-1000 Relay Emergency Valve that is still widely used in many countries. The A-1000 was innovatively engineered being the first air valve to ever use rubber “O” ring seals. In addition, the valve pioneered the concept of a removable cartridge or “plug unit” that was a trademark of all early Sealco valves. Many of our air valves today still incorporate a plug unit for a “quick fix” that can substantially reduce a trailer fleets ongoing maintenance costs.

In 1952 C. Roy Herring, Mr. Seale’s 27 year old nephew from Colorado, joined the firm as a draftsman. The company moved from Los Angeles to City of Industry in 1957, building their own 20,000 square foot building. Over the years, Mr. Herring became involved in the engineering and sales aspects of the company and in 1961 he purchased the company from Mr. Seale beginning the next phase of the Sealco organization.

In 1991 Mr. Herring brought Jerry C. Holland into the company as the General Manager. Mr. Holland, who had an accounting background as a chief financial officer, made a

number of strategic moves to rebalance and re-energize the company, among them moving the Sealco manufacturing facility from City of Industry, California to Phoenix, Arizona in 1992.

In 1996 Mr. Holland purchased controlling interest in the company from Mr. Herring who sold the remaining shares to other Herring family members. That same year, Sealco entered into a long term, contract with Rockwell Wabco, now ZF Wabco Commercial Vehicle Control Solutions, to distribute their ABS systems and other products to trailer OEMs in North America. In 2001, Sealco began manufacturing electrical wiring harnesses for both air braked and electrically braked commercial trailers.

What began in 1939 in a small, non-descript building as the Homer T. Seale company, evolved into Sealco Air Brakes, Sealco Air Controls and eventually Sealco Commercial Vehicle Products. Over eight decades of growth later, Sealco is clearly recognized as the leading supplier of air brake & air suspension valve products to the commercial trailer industry in North America, as well as exporting products worldwide and a quality supplier of electrical wiring harnesses for commercial transportation.

MARKET MATURITY

The design & manufacture of the first Sealco air valve was done after a careful study of what the trucking industry wanted in a product. Easy & inexpensive to service, a soft brake application, four application delivery ports & full braking pressure even if reduced tractor pressure were the criteria used to develop the A-1000 Relay Emergency Valve. While designing & manufacturing a better air brake valve was a good first step, it still had to be sold into the marketplace. Obviously, there was no aftermarket for the product & OEMs were apprehensive to use a new design on their trailers that hadn’t been proven in the real world. So Sealco took the valve directly to the trailer fleets to demonstrate their superiority.

The design & manufacture of the first Sealco air valve was done after a careful study of what the trucking industry wanted in a product. Easy & inexpensive to service, a soft brake application, four application delivery ports & full braking pressure even if reduced tractor pressure were the criteria used to develop the A-1000 Relay Emergency Valve. While designing & manufacturing a better air brake valve was a good first step, it still had to be sold into the marketplace. Obviously, there was no aftermarket for the product & OEMs were apprehensive to use a new design on their trailers that hadn’t been proven in the real world. So Sealco took the valve directly to the trailer fleets to demonstrate their superiority.

As the years went by, increasing numbers of fleets embraced the product & began to request Sealco valves on their new trailer builds. By the mid-1950s, Sealco had successfully established their product at the fleet & OEM levels of the trailer market. This level of penetration eventually created an aftermarket for the valves as they needed to be replaced.

Sealco continued to introduce innovative air valves to the industry & by the 70s they had acquired about one third of the air valve market at the trailer OEM level. During this time the first attempt was made at instituting commercial vehicle Anti-Skid systems but it ended in failure. Sealco was instrumental in helping the trailer OEMs get back on a workable platform for their air brake systems. This period really helped establish Sealco as a tier one supplier to the commercial trailer industry. In the early to mid-90s, Sealco’s marketing became more focused on discovering & selling trailer OEMs directly.

We created a trailer OEM database that allowed us to point our efforts toward the non-standard OEMs while still servicing those OEMs who were standard on Sealco products. At the time there were over 350 commercial trailer OEMs in North America.

database that allowed us to point our efforts toward the non-standard OEMs while still servicing those OEMs who were standard on Sealco products. At the time there were over 350 commercial trailer OEMs in North America.

When commercial ABS systems were reintroduced to North America in the 90s, Sealco was well positioned & partnered with joint venture Rockwell/Wabco (now ZF Wabco) to quickly achieve tremendous success in the market. This product combination helped drive our market penetration even further & dominated the competition in the trailer industry. Today, with over 750 air braked trailer OEMs in North America, Sealco has the enviable position of being standard at over 85% of those manufacturers for Sealco valves & Wabco ABS/RSS products.

In the early 2000s, l ooking for additional product lines to offer to our trailer OEMs, Sealco designed, developed & began to manufacture electrical wiring harnesses for commercial trailers. We have developed some unique features to our harnesses such as our bayonet connection for seven conductor main cables. This venture brought us into the market for electrically braked trailers as well since the valves & ABS were exclusive to the air braked trailer market. Today Sealco commands a strong presence in the electrical harness business for air & electrically braked trailers in North America & is growing all the time. In addition to all the Sealco products mentioned above, we also design & produce custom air valves & electrical harnesses to meet the specific requirements unique to the customer’s needs.

ooking for additional product lines to offer to our trailer OEMs, Sealco designed, developed & began to manufacture electrical wiring harnesses for commercial trailers. We have developed some unique features to our harnesses such as our bayonet connection for seven conductor main cables. This venture brought us into the market for electrically braked trailers as well since the valves & ABS were exclusive to the air braked trailer market. Today Sealco commands a strong presence in the electrical harness business for air & electrically braked trailers in North America & is growing all the time. In addition to all the Sealco products mentioned above, we also design & produce custom air valves & electrical harnesses to meet the specific requirements unique to the customer’s needs.

COMPANY CULTURE

COMPANY CULTURE

As a privately held corporation, Sealco has the ability to operate in a nimble manner compared to the public corporation giants in the industry. We have the ability to look at long term goals & programs instead of having to focus on quarterly profits. This results in faster & better decisions that ultimately benefit our customers. Sealco is the only manufacturer of air brake valves in the world that can boast that our products are 100% designed, manufactured & assembled in the U.S.A. Our competition, while they may have some facilities in the U.S., predominantly manufacture & assemble their valves in other countries. We buy, build & employ in America and are very proud that we alone can stamp our air valves with a Country of Origin stamp Made in USA. We believe that the formula for success is really pretty simple. Take care of our customers by doing the right things in a timely manner day, after day, after day, after day. We return all phone calls & emails every day if possible. Our phones are answered by a real person, not a computerized menu. Our customers can always get ahold of their Regional Manager or any staff at our plant from Customer Service, to Engineering to Management. Whoever the customer reaches, takes ownership of the issue or problem until it’s resolved. Between Sealco’s Regional Managers & our internal Engineering & Technical Departments, we offer the finest air brake system technical expertise in the industry today. No one can match Sealco’s service. Sealco’s quality, price, selection, availability, serviceability & value along with our technical expertise & service are what has put us on top & keeps us there. This is how we remain the industry leader in a very competitive market.

SEALCO OPERATIONS

Arizona Facility

Sealco’s primary facility is located in our company owned 70,000 square foot building in Phoenix, Arizona. This location allows Sealco the benefits of rapid deliveries from our numerous long term West Coast suppliers and our two inter-related companies in Southern California. It also provides for a favorable labor supply and rates as well as the overall business friendly climate of Arizona. Our corporate offices are maintained at this facility as well as the design engineering group, an extensive specialized laboratory for research and development, quality assurance team and a state-of-the-art CAD/CAM drafting department with solid model & 3D capabilities. The production floor is organized into receiving, component parts inventory, machine shop, valve and testing assembly, harness manufacturing and testing, finished goods inventory and shipping areas.

Indiana Facility

We ship our products to the 19 U.S. states west of the Mississippi River from Phoenix as well as all of our export orders around the world and bulk shipments to our Indiana warehouse facility.

The greatest volume of heavy duty commercial trailer manufacturing occurs in the mid-western portion of the United States. In order to provide the best possible service to our trailer OEM and aftermarket customers in this area, Sealco established a warehouse facility in Indianapolis, Indiana in 1996. Our company owned 20,000 square foot facility here houses our finished good inventory of air valves, electrical wiring harnesses and ZF Wabco products where we ship to the 31 U.S. states east of the Mississippi River.

Valve Production

The heart of the Production Department activities for valves in the Phoenix, Arizona facility is the assembly area. The floor is divided into eight separate and different assembly cells. Seven of these cells concentrate on a specific family of valves while the eighth assembly cell specializes in low volume parts that do not easily fit into the other seven cells. This configuration allows for the greatest flexibility in producing the ever-changing product mix to meet our inventory needs while reducing assembly down time by compartmentalizing valve products into groups that utilize similar component parts. This process is particularly important for a company like Sealco where products are manufactured for inventory in finished goods, not to order. Sealco offers hundreds of different air valves to the market utilizing thousands of different component parts.

The current assembly configuration allows ample opportunity for the expansion of the assembly cells as well as the possibility of additional assembly cells. Sealco currently produces approximately 6,500 air valves a day and has the ability to expand production to 8,000 valves per day all within a single shift on a 40-hour work week.

Electrical Harness Production

In another section of the Phoenix facility, custom electrical wiring harnesses are made to customer’s specifications. Here areas for cutting & stripping, crimping, sonic welding, over molding, testing and final assembly are located. Each wiring harness component moves through these stations for production and then is assembled into a complete harness at the end. Due to the adverse environment that the harnesses are intended to operate, predominantly underneath commercial trailers, most connections are sealed by overmolding the areas of connection with PVC in dedicated molding machines. Terminals that will connect with lights are also overmolded to seal out as many contaminants as possible. Main cable connections are made with our unique bayonet connector and other smaller cables use sealed overmolded connections as well.

Quality Control

Quality Control

Since our inception, Sealco has always strived, and remains committed to being today, a manufacturer of the highest quality products possible while remaining competitive in the marketplace in terms of price and delivery times. Specifications of thousands of component parts are determined by our in-house Engineering Department down to the material compound and coating of every O-ring and the plating and load characteristics of every spring.

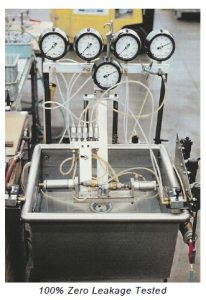

As component parts are received, they are tested in the Quality Control Department to assure that they are in compliance with the required design specifications. After assembly, the final step in Sealco’s quality control process is that 100% of the air valve manufactured must pass a performance and zero air leakage test before they are added to the finished goods inventory. Our custom designed test fixtures are utilized to seal various ports of the valve which is then pressurized at various psi levels to replicate real world applications and then submerged in soft water to prevent corrosion. The test operator then monitors the various test gauges on the test fixture to review the valves performance. The operator also checks the valve in the water tank for any air bubbles which will show the slightest leak often not visible on the gauges alone.

When electrical wiring harnesses are complete, they are 100% tested for their proper continuity of the wiring on custom light boards. They are also subjected to a high potentiometer test whereby a momentary shock of high voltage is applied to assure the electrical insulation of the connections.

Services

From the beginning, Sealco has always produced high quality products, on time and at a competitive price. But where we really outshine the competition is in the extraordinary customer service we provide. It begins when you call our facility and the phone is answered by a person, not a machine with robotic messages instructing you what numbers to push for a given situation. Our Customer Service Representatives efficiently handle all aspects of our customer’s orders including entry, modification, expediting, shipping, tracking and returns.

When it comes to technical assistance, no one in our industry can surpass Sealco’s reputation. Our 10 Regional Managers across North America are fully qualified to troubleshoot air brake system problems and have been with us an average of 18 years and in the industry an average of 31 years. Internally, our Engineering Department technically coordinates with the Regional Managers and assists in answering questions from customers that contact us directly. Our Engineers utilize our air brake systems lab and direct our lab technicians to recreate specific issues with air systems and find solutions to the problems. One call to Sealco can, and often does, bring all of these functions together to be certain that the proper response to any air brake system problem is found with all possible speed.

If more information is needed to resolve an issue than can be gathered over the phone or through email, our Regional Managers are available to personally visit the customer. Armed with sophisticated computer programs and pneumatic test equipment, they can perform pressure balancing and application and release timing tests. Actual color graphical print outs of these tests virtually depict the results and provide concrete evidence of the performance of the air system.

In addition to calling on our customers on a regular basis, our Regional Managers conduct instructional classes each year at no charge explaining air brake systems from their basic principles to the operation of ABS and RSS systems. These classes are aimed at educating our OEM and aftermarket customers as well as fleets in the belief that a better understanding of air brake systems benefits everyone.

Personnel

As with most successful businesses, Sealco’s most important asset is comprised of our dedicated employees. A testament to the positive working environment Sealco enjoys in its relationships can be found in their longevity. The Sealco employees engaged in outside sales and service have been with Sealco an average of 18 years and have been in the industry an average of 31 years. Some of our employees in our primary Phoenix facility have been with the company over 30 to 40 years. While these statistics speak for themselves, they exist for many different reasons. Excellent compensation, offering a wide choice of employment benefits, operating with a minimum number of management layers and fostering a sense of family in a corporate environment all contribute to Sealco’s success in the retention of our key employees. As our company continues to grow, we will become ever more reliant upon our employee’s ability to balance our industry’s technological advances with the reality of our customer’s needs in the marketplace.

DOMESTIC MARKET

Sealco’s products are distributed to and utilized by customers around the world. The United States is naturally our largest market and here we employ 6 Regional Managers responsible for all technical sales and service as well as training in multi-state territories. Over many decades, our Regional Managers in the U.S. have developed very strong relationships with the trailer OEMs and their employees in purchasing, engineering and production departments.

These OEMs have come to trust and rely on Sealco to advise them regarding air brake systems design, construction and to solve any technical issues that may arise. In the U.S. alone, over 550 commercial trailer OEMs use Sealco as their standard or preferred supplier of air brake valves. This equates to an almost 90% market share making Sealco by far the leading supplier air brake valves to trailer manufacturers in the U.S.

In addition, we maintain a high level of penetration in the heavy-duty aftermarket through our personal attention, education and our high quality of service to the aftermarket distributors focusing on their needs. Sealco has representation of our products in every geographic area of the country. As the heavy duty aftermarket continues to grow and consolidate, Sealco is increasingly viewed as the air valve supplier that provides the best products for the market due to our value added services of technical support, product knowledge and general ease of doing business with our company.

EXPORT MARKET

Sealco enjoys a presence on every continent recognized as one of the well-known manufacturers of air brake & air suspension valves. Excellent quality & technical support are synonymous with the Sealco brand worldwide. Outside the United States, Sealco operates with a combination of employees, master distributors and other independent agencies designed to best suit the needs of the individual country or region. Export sales represent about 35% of total revenues in over 45 countries around the world.

Canada ~ As one of our largest export markets and free trade partner to the north, Sealco employs 2 Regional Managers in Canada who offer technical sales and service functions to all Sealco customers. Canada’s CMVSS 121 rules are almost identical to the US FMVSS 121 laws so the OEM & aftermarket markets are very similar in nature. As in the U.S., Sealco has earned the position of being the standard air brake valve on the vast majority of trailer OEMs. Additionally, we have similar penetration of sales of ABS & RSS products using the ZF Wabco product line & continue to grow our sales of electrical wiring harnesses.

Mexico ~ As our other partner in North America, Sealco employs 3 Regional Managers who also provide technical sales and service information to all Sealco customers as well as offering technical assistance to other Latin American countries. DOT rules in M exico are again quite similar to the U.S. Many of our OEM sales in this country are accomplished through local distributors as the volume of the individual manufacturers is often quite small. However, where the volume is justified we sell directly to the larger OEMs. Our aftermarket distribution is very strong countrywide with multiple distributors in every regional area. Due to high employee turnover, repetitive training is common & the technical issues like end of line testing are quite challenging. Regional trade shows in Mexico provide a strategic marketing opportunity for existing & potential customers all over Latin America.

exico are again quite similar to the U.S. Many of our OEM sales in this country are accomplished through local distributors as the volume of the individual manufacturers is often quite small. However, where the volume is justified we sell directly to the larger OEMs. Our aftermarket distribution is very strong countrywide with multiple distributors in every regional area. Due to high employee turnover, repetitive training is common & the technical issues like end of line testing are quite challenging. Regional trade shows in Mexico provide a strategic marketing opportunity for existing & potential customers all over Latin America.

Central America & Caribbean ~ Sealco uses a number of independent representatives in this region that represent our products to both OEMs and the aftermarket. This area continues to use the U.S. type of air brake systems & lots of used equipment is imported from the U.S & Mexico. There are very few OEMs in the region so most of our sale are to distributors who in turn sell the few small OEMs that exist.

South America ~ Although the region predominantly uses the European air brake valves & ABS systems, Sealco has a strong presence in Colombia & Peru also selling a volume of business in Chile & Ecuador. At the OEM level, there are a couple of sizeable plants but most are small & informal. Most of them do not have business licenses to import components so the majority of our sales are to distributors to resell to the small OEMs & for the aftermarket.

Asia ~ Sealco is represented in this region by an independent contractor who has many years of experience in the trailer market & travels extensively throughout the area. He offers sales & technical services as well as training on air brake valve & total trailer air brake systems. While we have sizable sales to China, it is still a very small part of the entire market. We also sell a large number of products to Thailand where we have 4 master distributors who resell to OEMs & into the aftermarket. Vietnam is the most recent addition to our Asian sales where we sell a number of OEMs directly as well as into the aftermarket. Singapore sales remain significant but most of the business is resold into different countries In Asia. Additionally, we ship product to Indonesia & Malaysia & recently have begun to sell in Cambodia.

Australia & New Zealand ~ This is an important long-established region for Sealco. Both have similar DOT rules & we sell a large variety of valves into the area. We have several master distributors here who resell to both OEMs & the aftermarket network. They also create authorized brake kits which are required for OEMs & many of these kits contain several Sealco valves.

Europe ~ As the European air brake systems & regulations are different from the U.S., our business here is primarily done with OEMs who are producing trailers for the North American market. Therefore, there really is no aftermarket for Sealco in this region.

Africa ~ The continent primarily uses the European standard & so our sales in this region are small & basically used for aftermarket sales for equipment sourced from North America.

Middle East & India ~ Here we regularly sell to a number of companies that re-distribute our products across the region into the aftermarket. We also sell many Air Starter Valves here for industrial, mining & marine operations.

INTER-RELATED COMPANIES

Holland & Herring Manufacturing

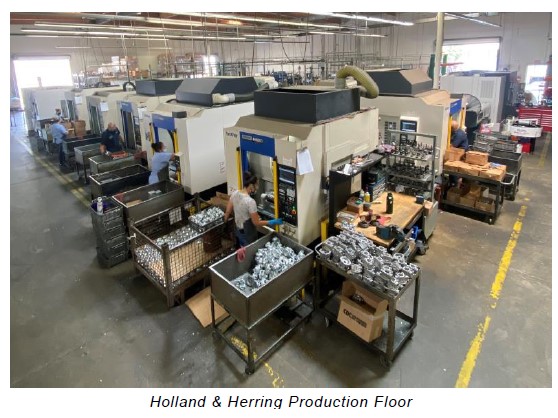

Holland & Herring Manufacturing, Inc., also known as H&H, was established in 1990 to serve as Sealco’s precision machine shop for air valve component parts. While Sealco & H&H have inter-related ownership and officers, they are maintained as separate entities. In H&H’s 15,000 sf facility, they receive raw cast metal parts daily along with other raw materials to machine and finish. All of Sealco’s precision machining, finishing, cleaning and thermal deburring processes are provided by H&H. This allows Sealco’s Engineering Department complete control over the quality of the parts produced.

H&H specializes in manufacturing high quality, high volume metal and plastic parts with exacting tolerances. To accomplish this, they utilize state-of-the-art CNC machines, such as Brother CNC mills and Takisawa CNC twin spindle lathes, both bar and gantry fed. These machines combined with specialty made conventional rotary transfer machines and a series of manual and semi-automatic conventional machines have assisted in supplying the commercial vehicle industry for the past 31 years. Quality is viewed as an ongoing process of both commitment and expertise in workmanship. For quality control, parts and components are continuously checked against print dimensions by not only the inspectors, but all employees during and after production, leaving little to no room for error.

Holland & Herring Production Floor

Additionally, H&H uses vibratory machines to meet specific surface finish requirements. All parts are washed, blown off and dried in their automated parts washing system where wash and rinse liquids are recycled through a patented dual-action liquid filtration system utilizing both a Cyclonic Chamber and an Air Hydro Skimmer. After the cast parts have been thoroughly cleaned of any residual cutting oils or grease, the parts are processed by one of H&H’s Surftran Thermal Deburring units. In the thermal deburring process, parts are placed in specialized metal baskets which in turn are lifted and sealed into an airtight chamber. A combination of gases is pressure fed into the chamber, then ignited to create a controlled explosion. This process allows the gas mixture to enter even the smallest internal cavities and blind holes to literally burn away excess flash or remaining burrs. Holland & Herring Manufacturing is dedicated to providing Sealco quality machined parts, prompt service and a commitment to minimize costs. Through consistent improvement in quality controls and staying current with the latest technologies, H&H is well positioned to provide Sealco’s growing requirements.

Additionally, H&H uses vibratory machines to meet specific surface finish requirements. All parts are washed, blown off and dried in their automated parts washing system where wash and rinse liquids are recycled through a patented dual-action liquid filtration system utilizing both a Cyclonic Chamber and an Air Hydro Skimmer. After the cast parts have been thoroughly cleaned of any residual cutting oils or grease, the parts are processed by one of H&H’s Surftran Thermal Deburring units. In the thermal deburring process, parts are placed in specialized metal baskets which in turn are lifted and sealed into an airtight chamber. A combination of gases is pressure fed into the chamber, then ignited to create a controlled explosion. This process allows the gas mixture to enter even the smallest internal cavities and blind holes to literally burn away excess flash or remaining burrs. Holland & Herring Manufacturing is dedicated to providing Sealco quality machined parts, prompt service and a commitment to minimize costs. Through consistent improvement in quality controls and staying current with the latest technologies, H&H is well positioned to provide Sealco’s growing requirements.

California Die Casting

The most significant material cost in manufacturing air brake valves is in the cost of die castings. Most bodies, covers, and several other components of Sealco air valve assemblies are high-pressure castings produced out of either special zinc or aluminum alloys by California Die Casting, Inc. in the Southern California area.

As it is commonly known, CDC was founded in 1996, and includes inter-related ownership of and officers with Sealco but are separate corporations. This relationship allows Sealco to carefully maintain costs and reduce lead times for their casting demands.

CDC utilizes state-of-the-art die cast machines ranging from 250 Tons to 800 Tons using both hot chamber zinc alloy die casting and cold chamber aluminum alloy diecasting, totaling 14 work cells. The hot chamber method requires the metal to be heated in the die cast machine where the cold chamber method requires the metal to be preheated in a separate furnace before transferring it to the casting machine.

CDC implements strict in-house processes and commits to consistently producing high quality products to the standards of the North American Die Casting Association. Only high-quality aluminum and zinc alloys are used for casting which results in premium metal parts. They conduct a wide range of inspection methods that include hand tools, test fixtures, gauges, destructive, shot monitoring and using the Coordinated Measuring Machine. Quality control and maintenance are practiced throughout the entire fabrication process. Computer-controlled equipment and automation assure parameters are met and maintained for quality, accuracy, and repeatability.

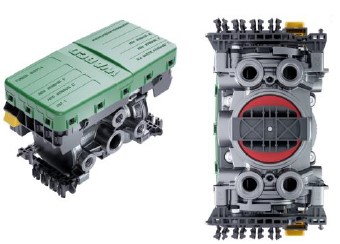

ZF WABCO PRODUCTS

With the implementation of government mandated Anti-Lock Braking Systems for heavy duty commercial vehicles in the late 90s, Sealco partnered with ZF Wabco, the industry leader in commercial trailer ABS. Together our two companies have been successful in establishing an over 80% standard position with the North American commercial trailer OEMs for ABS systems.

While ZF Wabco distributes their ABS and RSS products to the approximately 40 largest OEMs, Sealco distributes the ZF Wabco products to the remaining approximately 700 small to medium size air braked trailer OEMs in North America. Worldwide, over 6.5 million ZF Wabco trailer ABS systems have been sold and installed on vehicles.

As ZF Wabco’s trailer product lines have expanded with innovative products like Intelligent Brake Interlock and Tail Guard, Sealco’s role continues in distributing these products to the huge, small to medium size OEM market in North America. Sealco has been selected to also represent ZF Wabco in the launch of their new Trailer Cast program to soon be released.

Sealco’s extensive line of air brake and suspension valves work in coordination with the ZF Wabco product lines. Sealco’s ten Regional Managers in North America not only assist OEMs in specing, technical training, installing and troubleshooting ZF Wabco products, but they are often used as technical resources for issues with end use customers in the field. Their unique ability to understand complete air brake systems makes them invaluable in designing systems and technical support of the product lines.

In addition to its function as the distributor of ZF Wabco products to the small to medium size trailer market in North America, Sealco also serves as the West coast bonded warehouse for ZF Wabco ABS and RSS product lines.